MACHINERY FOR LINERS PACKAGING

Special purpose machinery Wadding of Pre-Cut or Tape form Liners in Caps and Cap Assembly.

- WADDING MACHINE

- INDUCTION MACHINE

We can offer a range of high speed Machines capable of fixing liners automatically in Plastic or Metal Closures.

Our machine are categoraised broadly based of the following types

Wadding (Liner Fixing) Machines for Fixing Pre-Cut Liners in Closures

a) Vacum Pick & Place Wadding Machine

This machine is capable of inserting and fixing the wads into the caps. The caps will be loaded into a Vibratory , Rotarty hopper or Elevator Hopper manually. The feeder supplies the caps adequately as required to the machine in the oriented fashion. The conveyor transfers the cap to a starwheel where the caps are indexed at predefined locations. The wads are loaded into a column chute (if in rolls) or into a vibratory feeder (if loose packed liners, normally for EPE or Foam liners) which is placed above the wad picking station. A vacuum picker assembly is placed below the column chute which picks the wad one by one and places on the top portion of the indexing starwheel above the caps. When the cap and the wad moves to the next station a pusher pushes the wad into the cap and is firmly fixed. The assembled cap will be counted and will exit from the coveyor. The machine will be capable of handling various types and sizes of caps and wads with the help of change parts.

Available with or without Hot Gluing System

Speeds Available – 60, 120 and 190 Caps per minute

Suitable for use with Two piece or One piece Liners and EPE liners

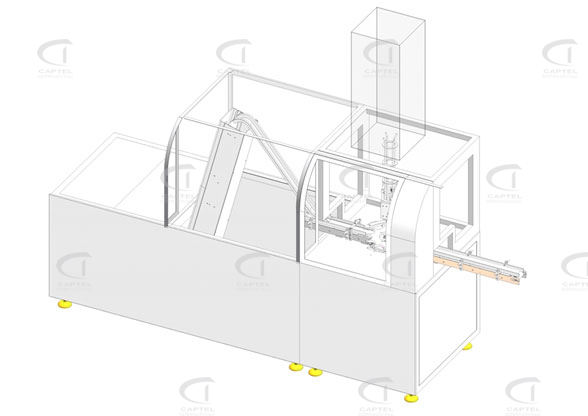

FULL OPTION MACHINE WITH ELEVATOR HOPPER FEEDER AND WITH COVERS

b) Dial & Punch Wadding Machine

The machine will be capable of inserting and fixing the wads into the caps. The caps will be loaded into a Vibratory hopper or Elevator Hopper manually. The feeder supplies the caps adequately as required to the machine in the oriented fashion. The conveyor transfers the cap to a dial where the caps are indexed at predefined locations. The wads are loaded into a column chute (if in rolls) or into a vibratory feeder (if loose packed liners, normally for EPE or Foam liners) which is placed above the dial, just before the wad punching station. The Liner drops on the top portion of the dial. When the cap and the wad moves to the next station a pusher pushes the wad into the cap and is firmly fixedThe assembled cap will be counted and will exit from the coveyor. The machine will be capable of handling various types and sizes of caps and wads with the help of change parts.

Available with or without Hot Gluing System

Speeds Available – 60 Caps per minute

Suitable for use with Two piece or One piece Liners and EPE liners

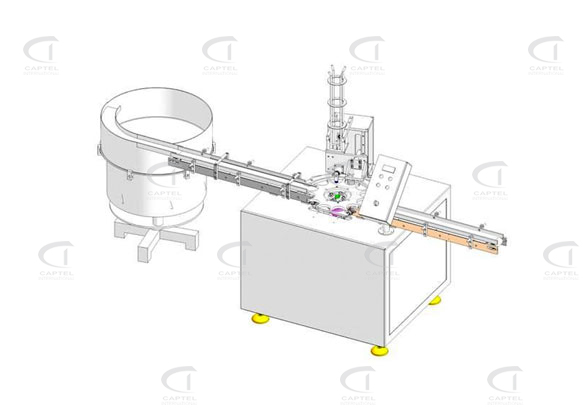

BASIC MACHINE WITH VIBRATORY FEEDER AND WITHOUT COVERS

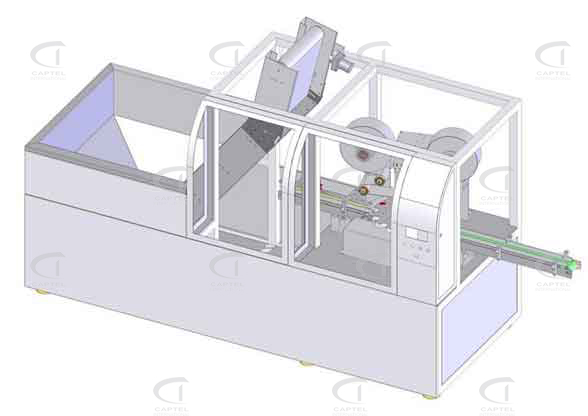

Liner Cutting & Wadding Machine

The machine is capable of Cutting Liners from Rolls and inserting and fixing these cut wads into the caps in a single operation. The caps will be loaded into a Vibratory hopper or Elevator Hopper manually. The feeder supplies the caps adequately as required to the machine in the oriented fashion. The conveyor transfers the cap to a dial where the caps are indexed at predefined locations. The Liners in Rolls are fed onto the In - feed rollers and cut just in time before the wad punching station. The Liner drops into the Cap and when the cap and the wad moves to the next station a pusher pushes the wad into the cap and is firmly fixed. The assembled cap will be counted and will exit from the coveyor. The machine will be capable of handling various types and sizes of caps and wads with the help of change parts.

Available with or without Hot Gluing System

Speeds Available – 60 and 120 Caps per minute

Suitable for use with Two piece or One piece Liners and EPE liners

We can offer a range of Sealing Machines capable of sealing liners on their containers, Manually and Automatically

Manual Induction Machine

Our Manual Induction machine is extremely simple to handle, carry and operate and is the perfect answer to your portable induction sealing needs. Plug the system into a standard wall power outlet and it is ready to operate. Set the power level and the timer to the number of seconds the container requires for a strong and secure seal. To seal, simply place the sealing head on the container's cap and press the trigger on the handle of the sealing head. The timer counts down to zero as power is applied into the cap to form the seal. Check the first few containers for seal quality. Adjust power and time until a firm, once the correct settings are reached, seals will be secure and consistent.

Semi Automatic Machine

This machine is designed for packagers who require a semi-automatic sealing process with low production volumes. The table top machine is compact and ideal for production environments where a bottle conveyor is not practical. Built-in guides ensure operators properly line-up containers for sealing. A digital timer lets the operator know when the sealing process is completed. Completely air-cooled/water-less operation. Seal a wide range of containers & closures.

Online Automatic Machine

Our Automatic Induction Sealing machines have been developed especially with a view to meet the exacting needs of the packaging industry.

Compact all-in-one design: Easily Movable : The machine is mounted on a wheel based water-cooling unit which provides mobility. Easy for line relocation.

Available in 1 kv, 2 kv and 3 kv capacity